How A Lights Manufacturer Increased Their Business Performance Up to 100% in One Year

Want to increase your business performance?

There is no better way to do that than with a data-driven process.

Today, I’m going to show you how a manufacturer of lights in Australia improved their business by 100% in one year.

And they were able to accomplish this feat while battling financial troubles in their country at the time.

In this case study, I will show you the entire data-driven process they used - step by step.

One of our first clients in the manufacturing industry dealt with lights manufacturing based in Australia. They pride themselves in innovating their production towards better lighting for the world. Their business mainly revolves around creating the best lighting products through state-of-the-art engineering.

Like many companies, the Australian lighting company struggled with forecasting and supply chain management. It had to consider several aspects of the product design such as heat dissipation, thermal engineering, lighting intensity, and color temperature, among others. With the complexity and degree of customization in this type of industry as well as added pressure on ensuring product quality and lead time required for production, this lighting company found it challenging to analyze the data on consumers' demand and they cannot rapidly respond to changes to demand and supply.

For the leaders of the lighting company, failure to accurately forecast the demand and supply will entail negative consequences on their business’s operations, growth, and reputation. Inaccuracies in supply and demand forecasting will lead to unnecessary inventory and production costs, serious drawbacks in terms of dissatisfied customers, inability to meet demand resulting in lost sales, bad word-of-mouth, and inefficient workflow.

Initially, they were reluctant because they felt that the status quo was enough. But they realized the concept of lost opportunities. They were losing profits by not making data-driven decisions. Amid the financial crisis in Australia at that time, they realized that it was now time.

The right time was to take advantage of the slow economic incline, while the economy is bouncing back from the crisis. They made the call to "Clean up and Gear up" their data and analytics processes to be the first movers when the economy fully recovered.

This is the main reason why the lighting company sought the service of DataHyv to build and integrate a data warehouse and data analytics platform to aid them in forecasting demand and supply.

How this Company Boosted Their Business Performance With Datahyv

DataHyv helped a leading lighting manufacturing company in Australia be able to forecast demand and supply that helps improve accountability for the forecast and enables continuous improvement across the company.

Within a year of working with Datahyv, they achieved:

- 90% increased lead conversion

- 90% increased accuracy in data and forecasting

- 80% increased optimization of new product launches

- 50% increased profits

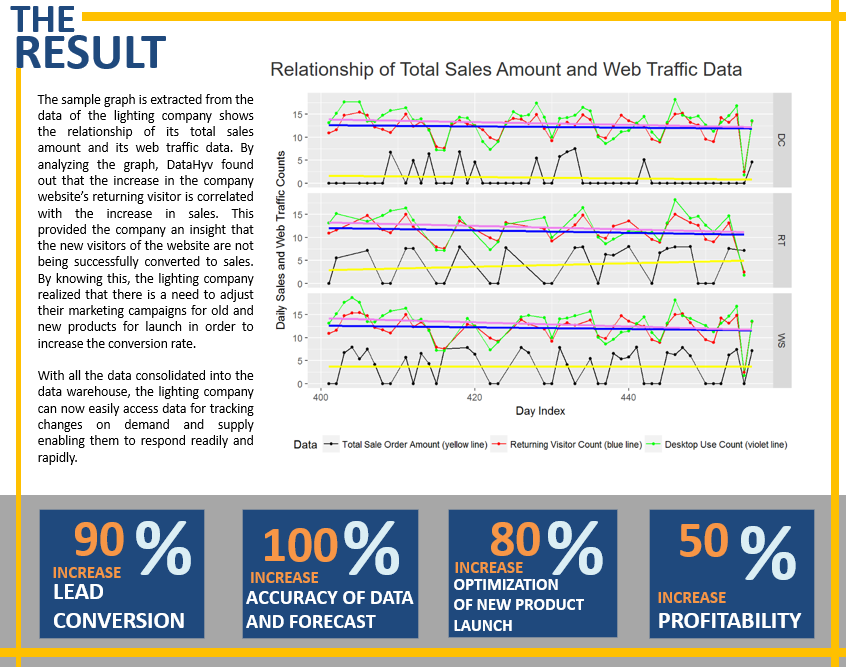

DataHyv found out that the increase in the company website’s returning visitors is correlated with the increase in sales. And analyzed that new website visitors were not being successfully converted to sales.

After realizing this, the lighting company adjusted their marketing campaigns for old and new products for launch to increase the conversion rate.

With all the data consolidated into the data warehouse, the lighting company can now easily access data for tracking changes on demand and supply enabling them to respond readily and rapidly.

This became their unique edge against their competition when COVID-19 came and blitzed its negative impacts across the world. They were able to utilize the data-driven process laid out by Datahyv so they can thrive amid supply bottlenecks and volatile demand changes.

Here’s the exact six-step data-driven process they used to thrive during this pandemic:

1. Build a data warehouse.

DataHyv untangled the intricacies of forecasting by building a data warehouse for the company which will serve as the centralized platform for all data needed that are coming from disparate sources. This is a unified comprehensive database that merges all the business information coming from one or more data sources.

DataHyv’s cost-effective data warehouse allowed the lighting company to quickly access critical data from different and unrelated sources all in one place. It offers added support for data, in that they are designed to track, manage, and analyze information, to provide actionable business insights.

2. Extract business data.

Datahyv extracted the data from DEAR Inventory, Google Analytics, and a CRM tool which is Sharpspring. Here we were able to uncover the untapped sales opportunities, and more importantly, the underlying problems of the lighting company.

3. Clean up data for inconsistencies. Then segment customer profiles and sales channels.

The lighting company’s forecasting method is internally centered. They focus on sales, inventory, and operations only. So Datahyv cleaned up all data, both historical and present data with regards to the company’s sales, customers, suppliers, inventory, trends, products, and operations. Through the data warehouse, we were able to ensure that all inconsistencies, discrepancies, and redundancies were eliminated from their data system.

Upon cleaning up their data, Datahyv was able to identify where the customers were in the sales funnel. We helped the company successfully lead them throughout the process thereby increasing the company’s conversion rate and sales.

4. Analyze business reports based on historical figures to produce accurate forecasting.

After extracting all the necessary data from disparate sources into the data warehouse, DataHyv analyzed the data and created a forecasting model for the lighting company.

Throughout this process, DataHyv worked closely with the company leaders and decision-makers to ensure that the data warehouse provides them with what they specifically need for demand and supply forecasting.

We facilitated the company’s critical business activities by providing them with meaningful business insights necessary for planning and decision-making

5. Implement decisions based on findings from the analysis.

Upon receiving the business reports created by Datahyv, the lighting company revamped their business operations from planning to production to marketing. They used the data to pinpoint areas of improvement and create business resiliency.

6. Review and recalibrate as necessary.

Datahyv continues to provide continuous improvement across the company’s performance, operations, processes, and profitability. They even worked to recalibrate and adapt the system to respond to the changes brought by the pandemic.

So even during strict lockdowns and supply chain bottlenecks, the lighting company was able to thrive and make their business profitable with fewer costs. They did this all with drastically reduced labor costs and increased productivity in all aspects of the company.

Conclusion

Having a data warehouse and a seamless system of data analysis with clear, insights for decision-making is what made a lights manufacturing company in Australia thrive amidst the pandemic. Getting up to 100% improved business performance!

You too can make your company excel, even amidst a crisis, by following this data-driven step-by-step process.

If you found this case study compelling, I’d really appreciate you sharing this with your fellow business leaders.

And if you want to get your company to the same improvements, check out our data warehousing and analytics solutions. We will help you harness your data to take your business to thrive amidst all challenges.